Clinical Chemistry

The equipment chemically tests samples (Serum, CSF, Urine, etc.) that are derived from patients and analyzes the results to diagnose, treat, and determine the prognosis of the disease.

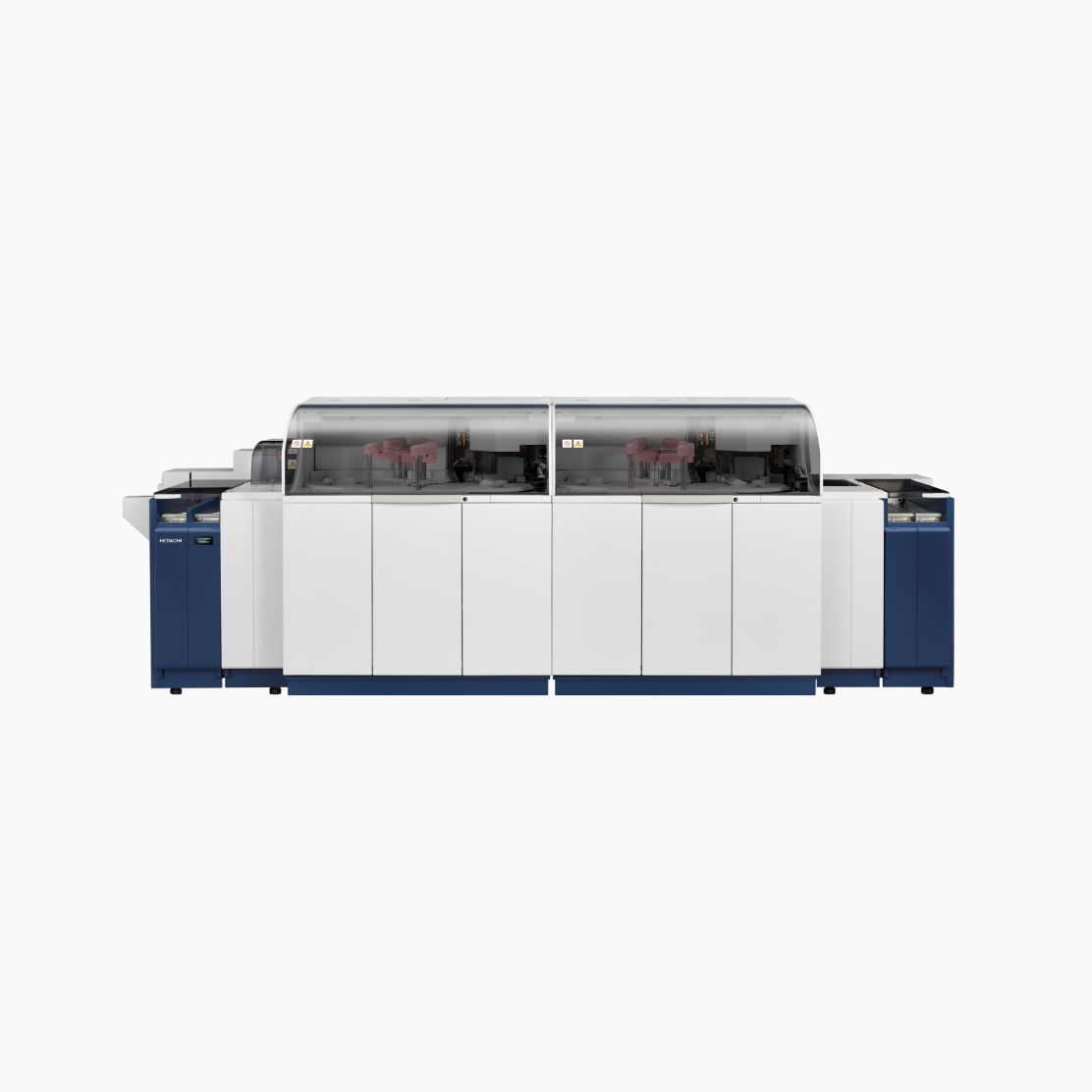

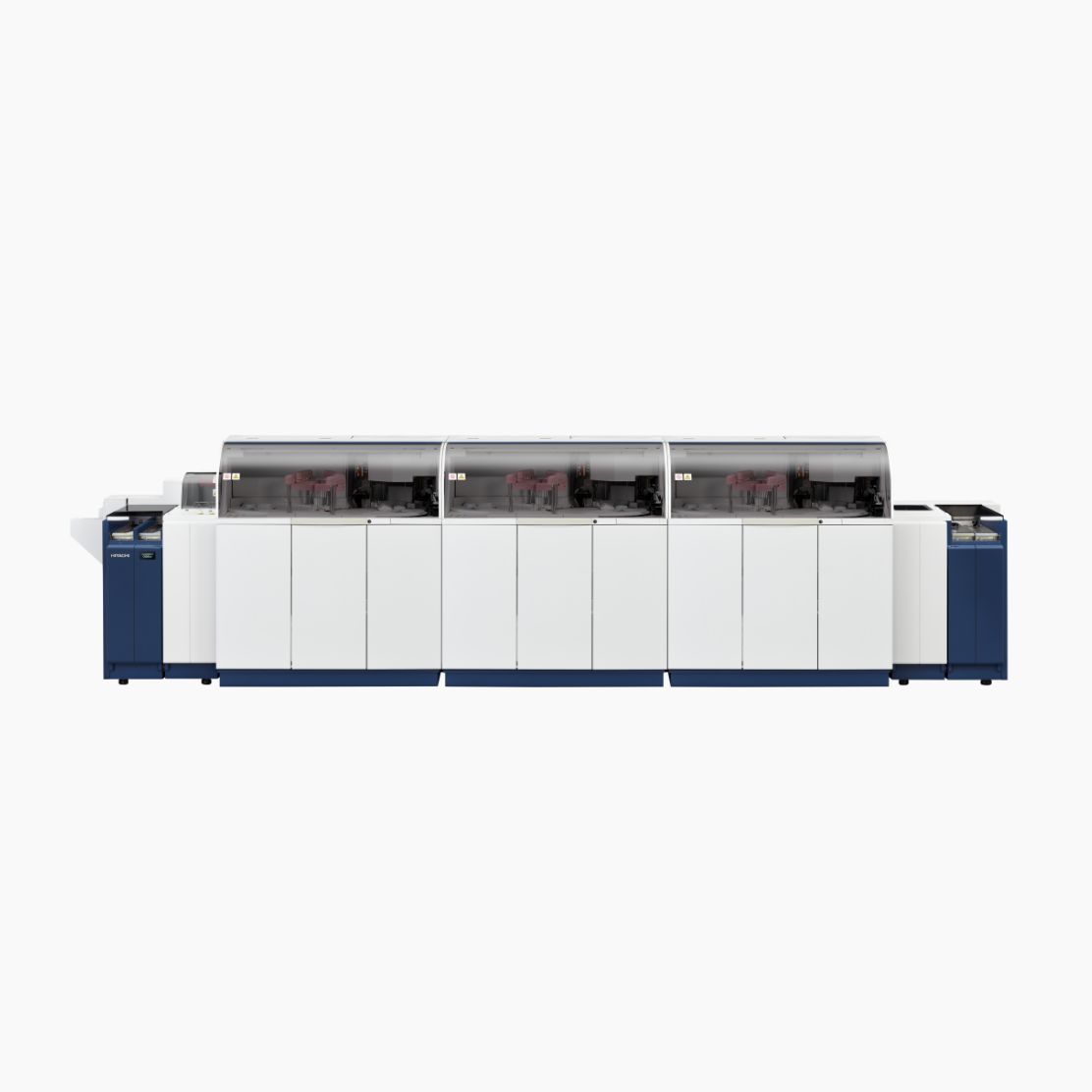

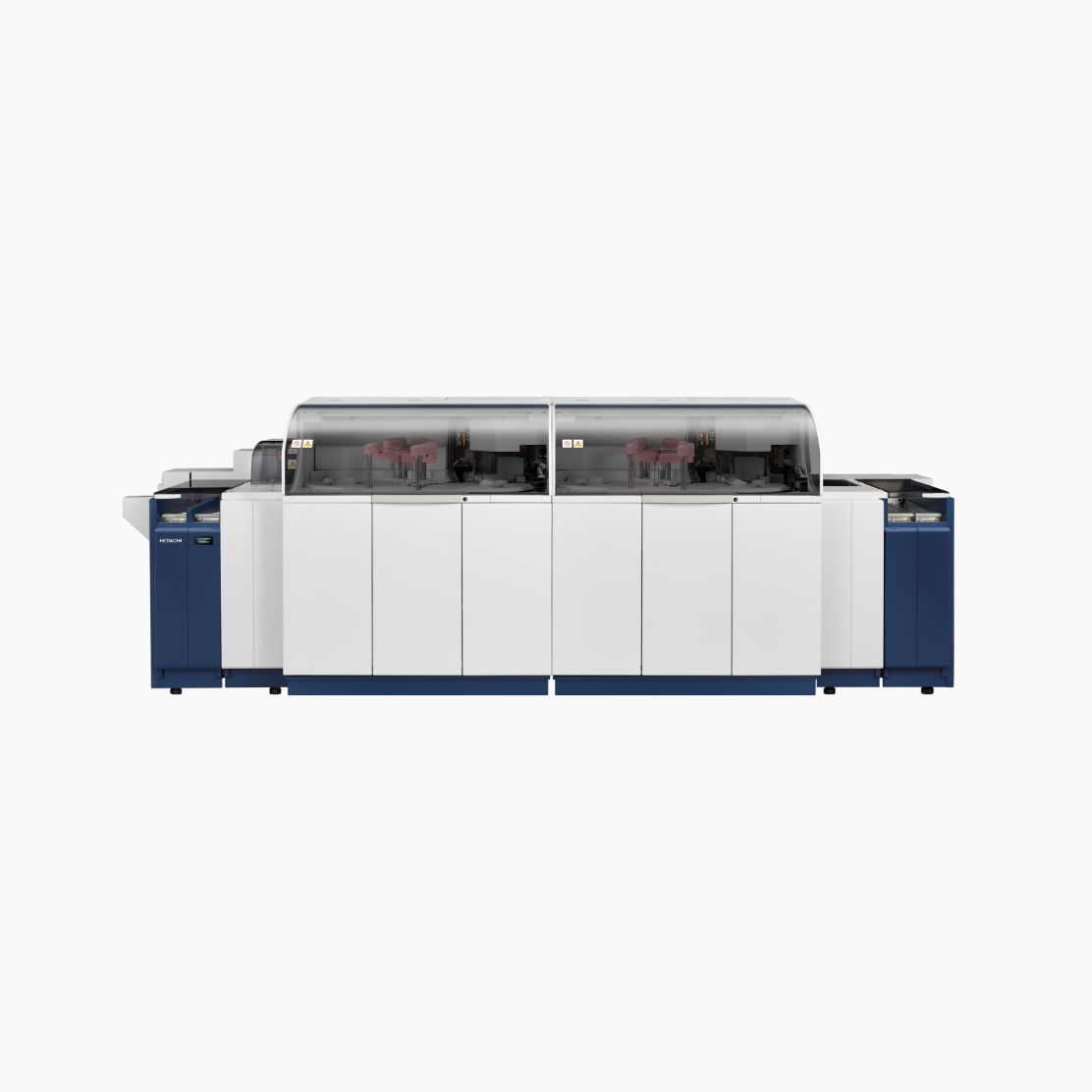

Labospect 008α

Up to 2,000 tests/module per hour- Photometric tests up to 2,000 tests/hour/Module

- ISE up to 1,800 tests/hour

- Combination of up to 4 analysis modules

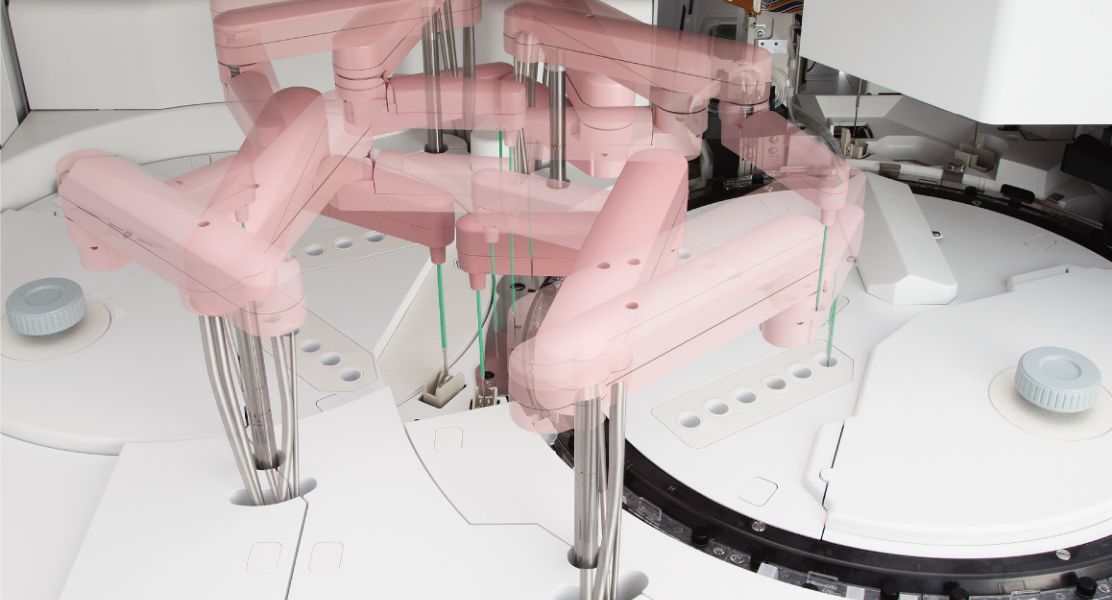

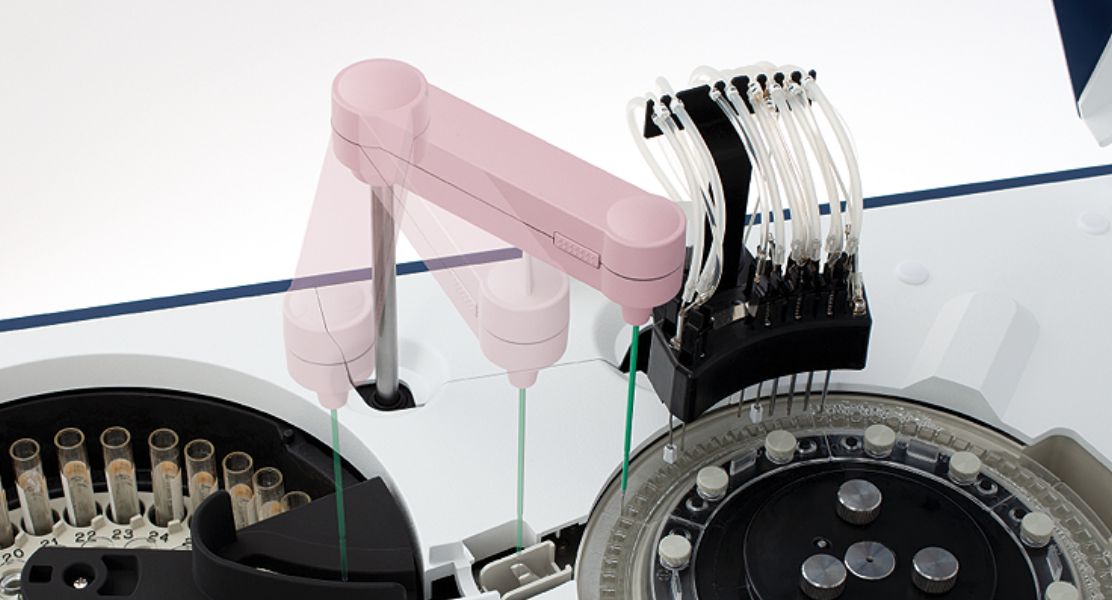

wo pairs of reagent probes (for reagent 1 and reagent 2) alternate in a 3.6 second cycle. Two-step rotation of the reagent probe results in efficient movement between the reagent disk and the reaction disk. One module can handle up to 2000 tests per hour by pipetting at a rate of 1.8 seconds per test.

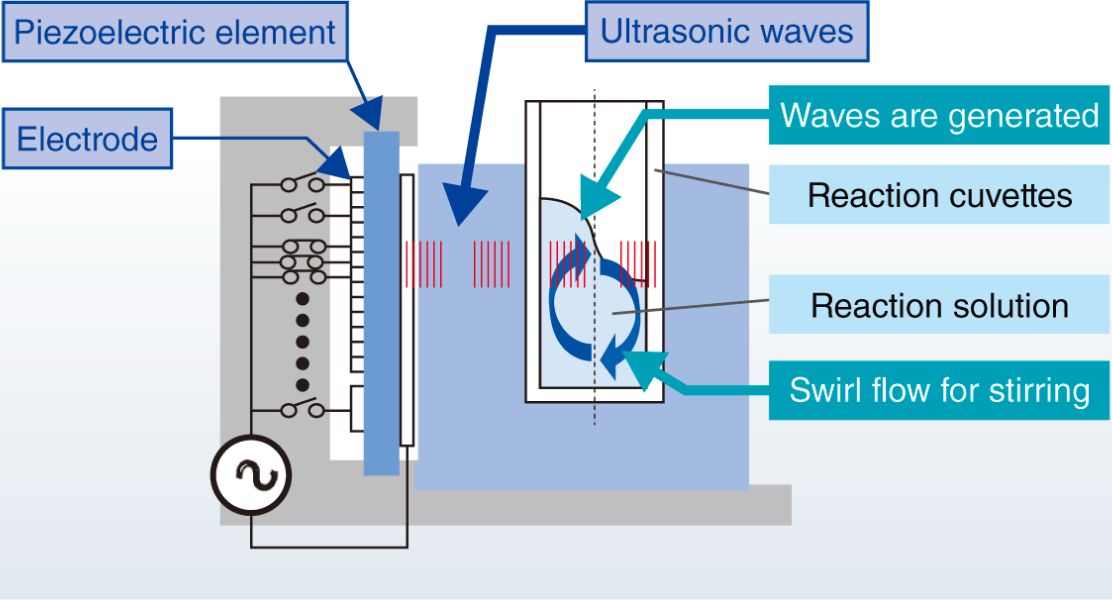

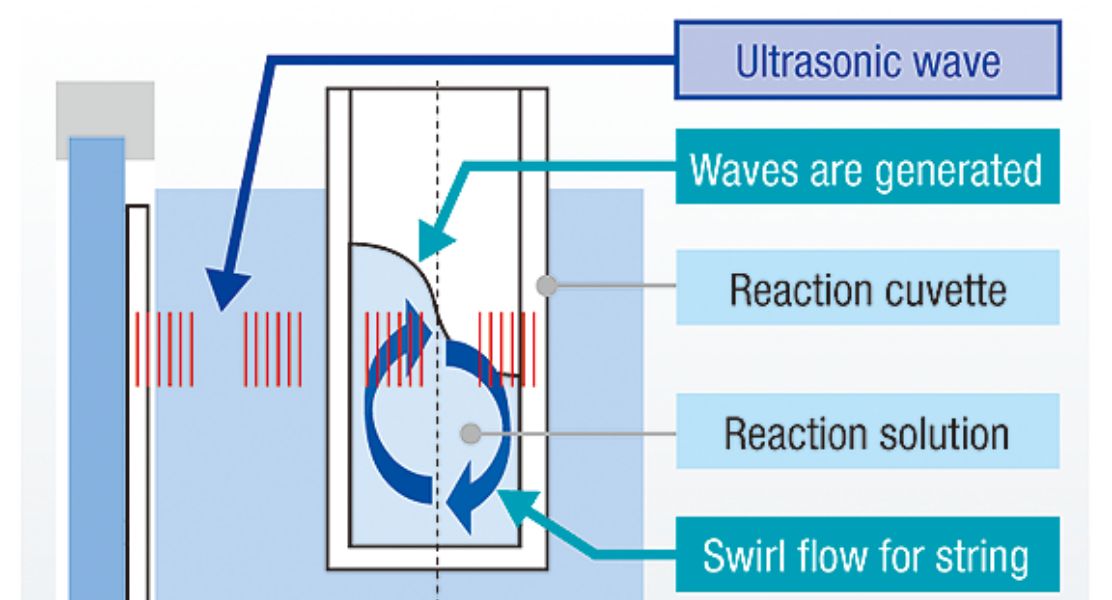

The ultrasonic wave generated by the piezoelectric element mixes the reaction solution in a non-contact manner. This stirring method can eliminate cross-contamination that can occur with stirring paddles. In addition, since there is no need to use washing water for the stirring device, the amount of water used and the amount of waste liquid can be significantly reduced.

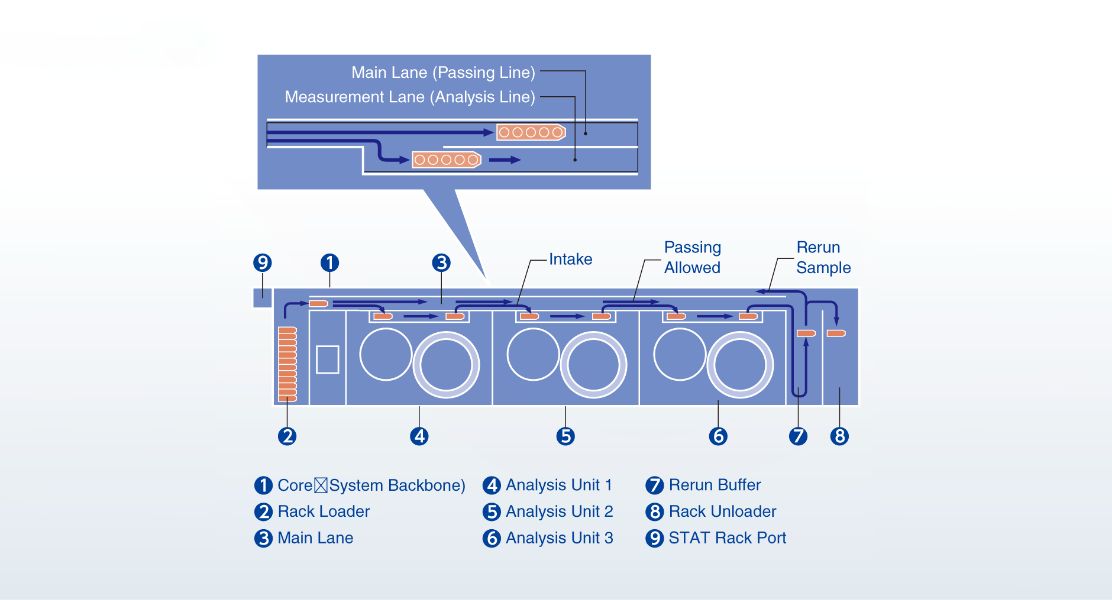

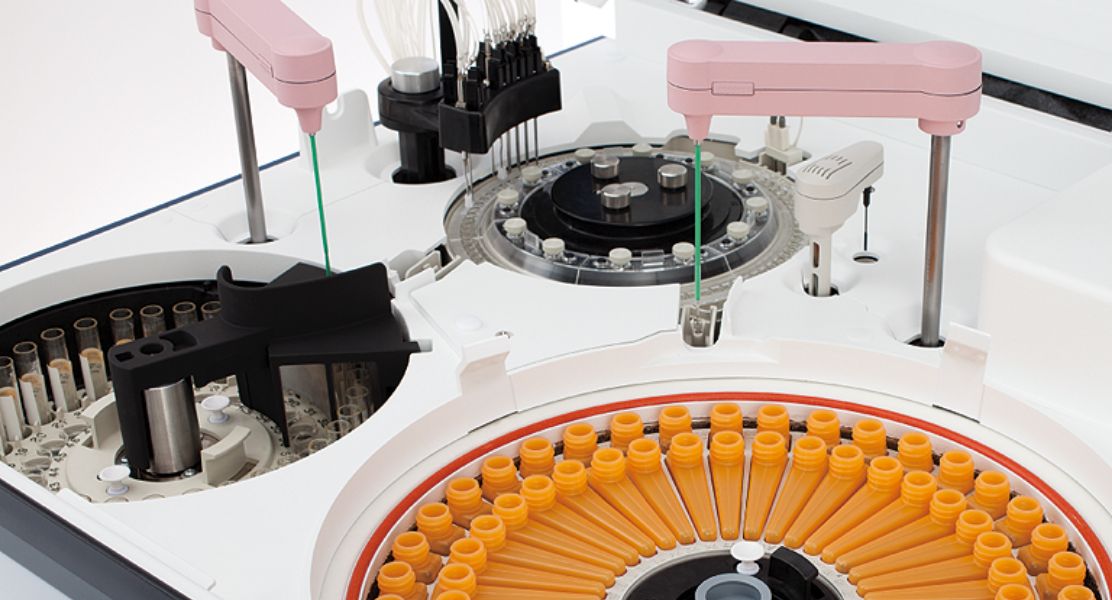

Samples are loaded into the Labospect 008α by a five-rack input system. Racks loaded into the loader are transported by a sample transportation unit comprising three lanes (main lane, measurement lane and return lane). The high-capacity sample loading area and intelligent rack transportation system help to enable efficient processing of a large number of tests on a large number of samples.

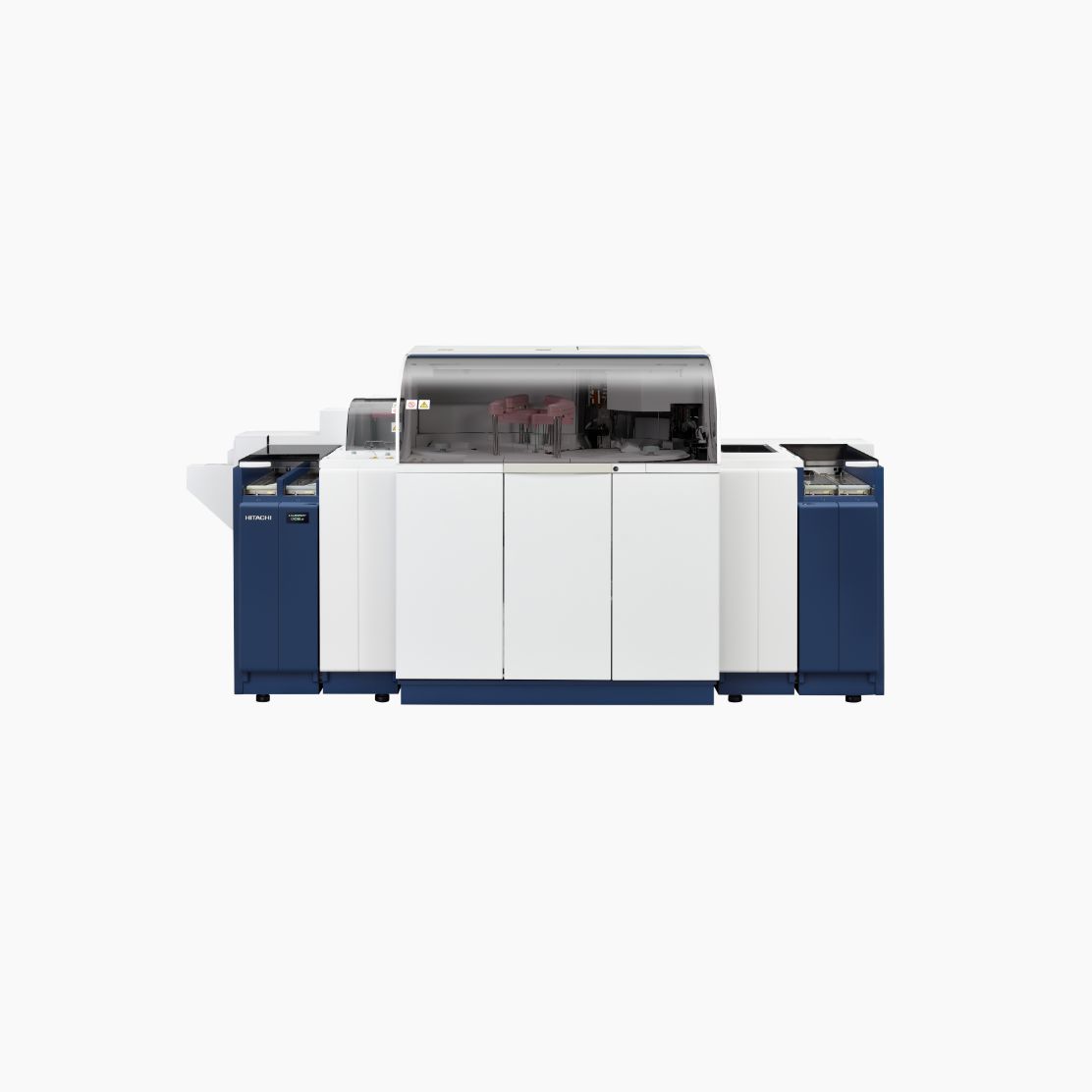

Labospect 006

Up to 1,900 tests per hour- Photometric test up to 1,000 tests/hour

- ISE up to 900 tests/hour

- HbA1c (optional) up to 500 tests/hour

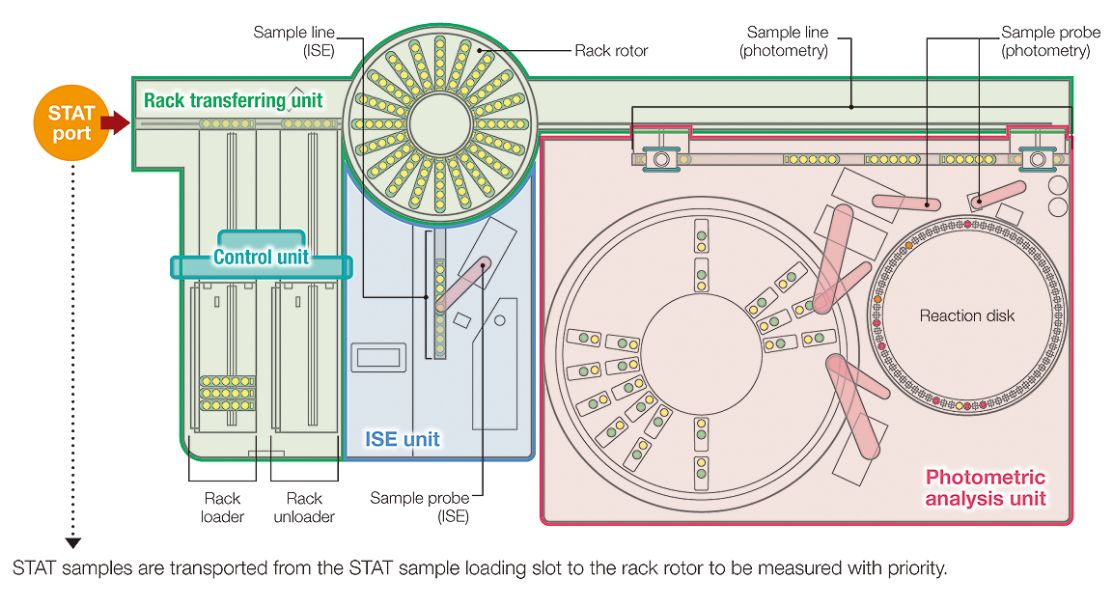

The 5-tube rack loaded in the sample loader is transported to the rack rotor and pulled into the sample line (ISE), and the sample is pipetted with the sample probe (ISE). After the sample pipetting for ISE, the 5-tube rack is transferred to the sample pipetting position for photometric analysis through the rack rotor. After pipetting the sample for photometric analysis, the 5-tube rack is moved from the sample line (photometric) to the rack rotor and returned to the sample unloader.

Non-contact stirring is achieved using ultrasonic waves. The contamination caused by the contact stirring mechanism is reduced to "zero," and the amount of water used and the amount of waste solution are also reduced.

Throughput: up to 500 tests / hour Adoption of the dedicated sample probe and dedicated cleaning function for HbA1c measuremnet have enhanced processing capacity for HbA1c measurement. Integrated measurement of HbA1c and clinical chemistry tests is possible.

3500

Up to 1,400 tests per hour- Photometric test up to 800 tests/hour

- ISE up to 600 tests/hour

- HbA1c up to 200 tests/hour

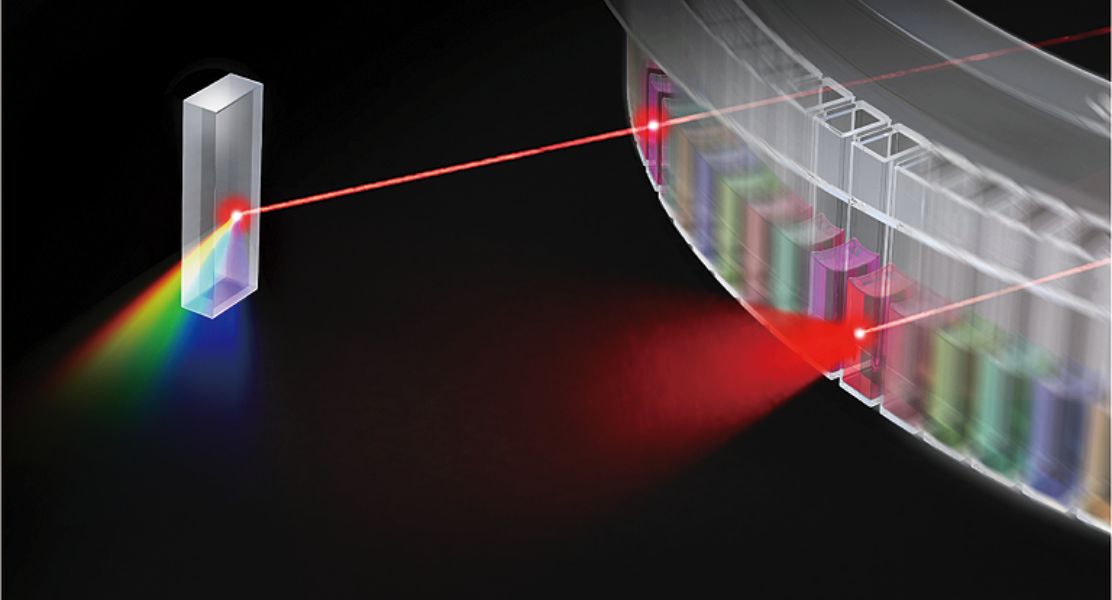

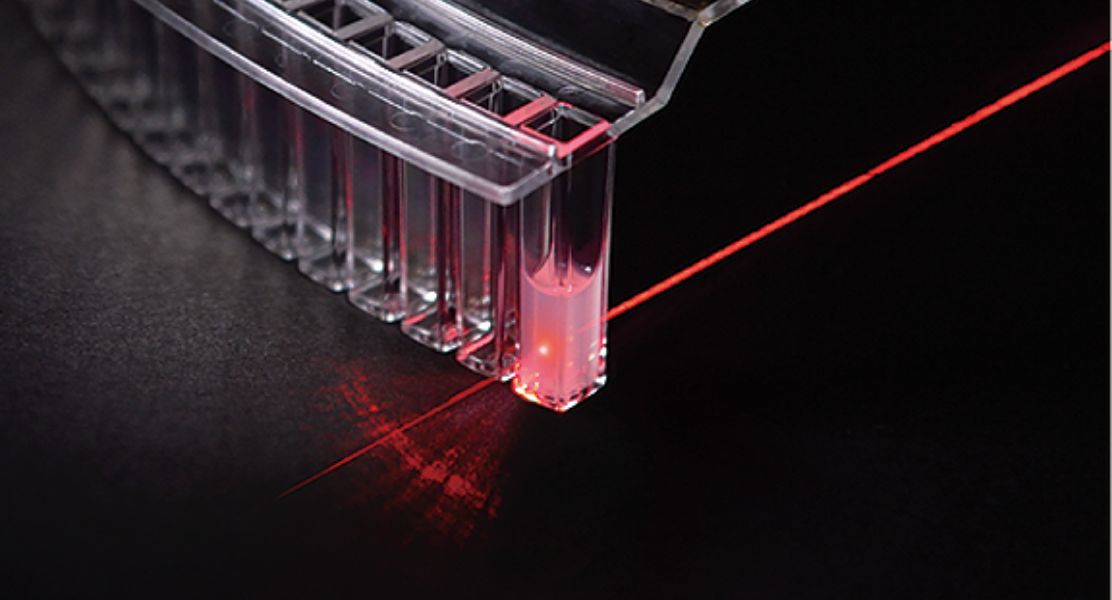

Since the launch of the first Model 400 in 1970, Hitachi has continued to develop technologies to support clinical laboratories. As a successor to this technology, the newly developed scattered light intensity analysis measurement technology provides the advanced Hitachi Auromatic Analyzer 3500. The Hitachi Automatic Analyzer 3500 includes a new technology that simultaneously performs scattered light intensity analysis to perform low-concentration measurements and absorbance analysis. Technology that expands the scope of examination with one measurement, increases the reliability of measurement results, and mounts various functions in a layout that is designed to be easy to use will contribute to an efficient workflow and future medical care.

Scattered light intensity photometer enables to measure low-concentration ranges with higher sensitivity, ensuring highly reliable test results.

With the "pipe operation" function that can program the maintenance items in advance, the user can perform the necessary maintenance efficiently on starting up the instrument and finalization of the instrument. And also, Reaction cuvettes are cleaned with detergent. This function can reduce the maintenance time after exiting routine.

3100

Up to 600 tests per hour- Photometric test up to 400 tests/hour

- ISE up to 200 tests/hour

The control unit is embedded the body of 720 mm width, 820 depth and 1,105 mm height. Up to 400 tests

Simple icons on a color touch screen are organized for easy operation with a graphical user interface (GUI). A control unit with a GUI arranged on the front of the instrument makes the sequence of operations very efficient from sample placement to the starting of the analysis.

With the "pipe operation" function that can program the maintenance items in advance, the user can perform the necessary maintenance efficiently on starting up the instrument and finalization of the instrument. And also, Reaction cuvettes are cleaned with detergent. This function can reduce the maintenance time after exiting routine.